Impact reduction

Material substitution potential

Most greenhouse gas emissions come from material extraction, resource management and design choices. This is where 80% of their environmental impact is determined.

Climate impacts per functional unit

Our materials are 100% fossil free. The material is sorted as wood end of life (EoL) at any recycling station globally. As PaperShell production is highly automated and energy efficient the Green House Gas (GHG) emissions or “CO2 costs” to produce one kg ready made component is exceptionally low. Latest LCA, Cradle to Cradle (C2C), including single life and incineration EoL, show 0.496 kg CO2e per kg PaperShell component which is 25% lower than the average of a Swedish lunch. 90-98% less negative impact than the same components made of plastics, fibre composites or metals.

The LCA diagram above compares the CO2e impact of the same component in different materials. This LCA is even calculated to PaperShell’s disadvantage, not including the potential of circularity and returning the biogenic carbon into the ground.

Material substitution

By switching materials in a new or existing products substantial environmental gains can be achieved fast and long before 2030. Below are some examples and you can also utilise our CO2-calculator to evaluate the impact reduction of your components by switching to PaperShell.

Wood (veneer) refers to thin slices of wood usually thinner than 3 mm that typically are glued together or mounted onto panels to produce flat or single curved panels for furniture, doors, flooring, etc. Apart from fossil based glues pressed moulded veneer components are free of fossil based carbons. There are two types of wood, 2D and 3D veneer. 2D veneer can be pressed in simpler single curved shapes while 3D veneer can be pressed in more complex shapes. 3D veneer is very expensive.

>50% CO2e reduction by using PaperShell instead

PaperShell gives higher design freedom than 3D veneer in terms of geometry, surface detail, etc. and is much more moist resistant, heat resistant and outdoor resilient. Main CO2e savings comes from production efficiency, reduced waste and higher yields.

Plastics (PP) is one of the most common and classic thermoplastics that can be reheated and recycled again without significant degradation. Unfortunately, many plastics are contaminated with additives and flame retardants, lost and/or burnt, and only about 42% of all plastics in the EU are recycled. PP is recycled to a much lesser extent. Plastics like PP are 100% fossil based and will release its fossil carbon in the atmosphere end of life.

>90% CO2e reduction by using PaperShell instead

PaperShell is a bio based and renewable allowing you to move away from a fossil (oil) based resource. If incinerated, your PaperShell component will only release atmospheric carbon. If brought back into nature PaperShell will store atmospheric carbon in the ground and add to soil enhancement and bio upcycling reaching net zero and beyond. Tooling price that is 30-50% lower than an injection molding tool.

Glass Fibre (GFRP) is a versatile material due to its inherent strength and weather resistance. Manufacturing of fibres uses large furnaces to melt silica sand, limestone, kaolin clay, fluorspar, colemanite, dolomite, and other minerals and is very energy intensive. The binders needed such as epoxy or PET resins are fossil (oil) based and hazardous flame retardants are frequently added. Recycling solutions for glass fibre composites are rare or non-existent in most regions globally.

>98% CO2e reduction by using PaperShell instead

With PaperShell you have much less environmental negative impact regarding many aspects. You have a renewable and controlled bio based resource from EU and your product will be sorted as wood EoL and can be returned to nature which is not possible with glass fibre.

Metal (Aluminium) is a strong and lightweight metal which is good for recycling. However, it requires a lot of energy to extract from Bauxite ore. To produce pure aluminium, 3 – 4 times more energy is required compared to producing iron. Huge amounts of both fossil fuel and electricity are used. The extraction is mostly in Australia, China, and South America. However, it takes 20 times less energy to recycle than to produce so keep this material in the loop.

>98% CO2e reduction by using PaperShell instead

A rule of thumb is a 2 mm thick component in PaperShell has the same weight and strength as a press molded component of 1 mm aluminium. In comparison, a PaperShell component will have >97% less environmental impact, >10% lower in price.

Endpoint impacts per functional unit (ReCiPe 2016)

But green house gases are just one dimension of planetary boundaries why aspects such as land and water use, resource depletion etc are equally important. At present a component of PaperShell’s total weighted single score per functional unit (EF3.0) vastly outperforms any other material in comparison made by third party, even components made of wood veneer.

Volume leads to major systematic impact reductions

As 80% of the negative environmental impact comes from material extraction, resource management and design choices, the true positive effects come from substituting materials to PaperShell, especially if this is done on a large scale. An interesting KPI by The Swedish Environmental Protection Agency (Naturvårdsverket) measures kg CO2e reduction per invested Swedish crown (SEK). Their average for the most promising Swedish greentech companies, where they by 2023 have invested 13.9 BSEK, is 1,67 kg / invested SEK.

If PaperShell contributes to substitution materials according to plan replacing materials such as wood (veneer), plastics (PP), glass fibre (GFRP) and metal (aluminium), the impact will be higher than 1,90 Kg CO2e / invested SEK equivalent to 3,4 Million CO2e tonnes saved from reaching the atmosphere.

If focus is merely on replacing the most environmentally problematic materials such as glass fibre and aluminium, the impact will be impressive and as high as 7,37 kg CO2e / SEK invested equivalent to 13,3 million CO2e tonnes in avoided emissions.

To give a reference, year 2029 alone will be equivalent to remarkable 872,000 tons, offsetting a staggering 363 million 15 km car trips.

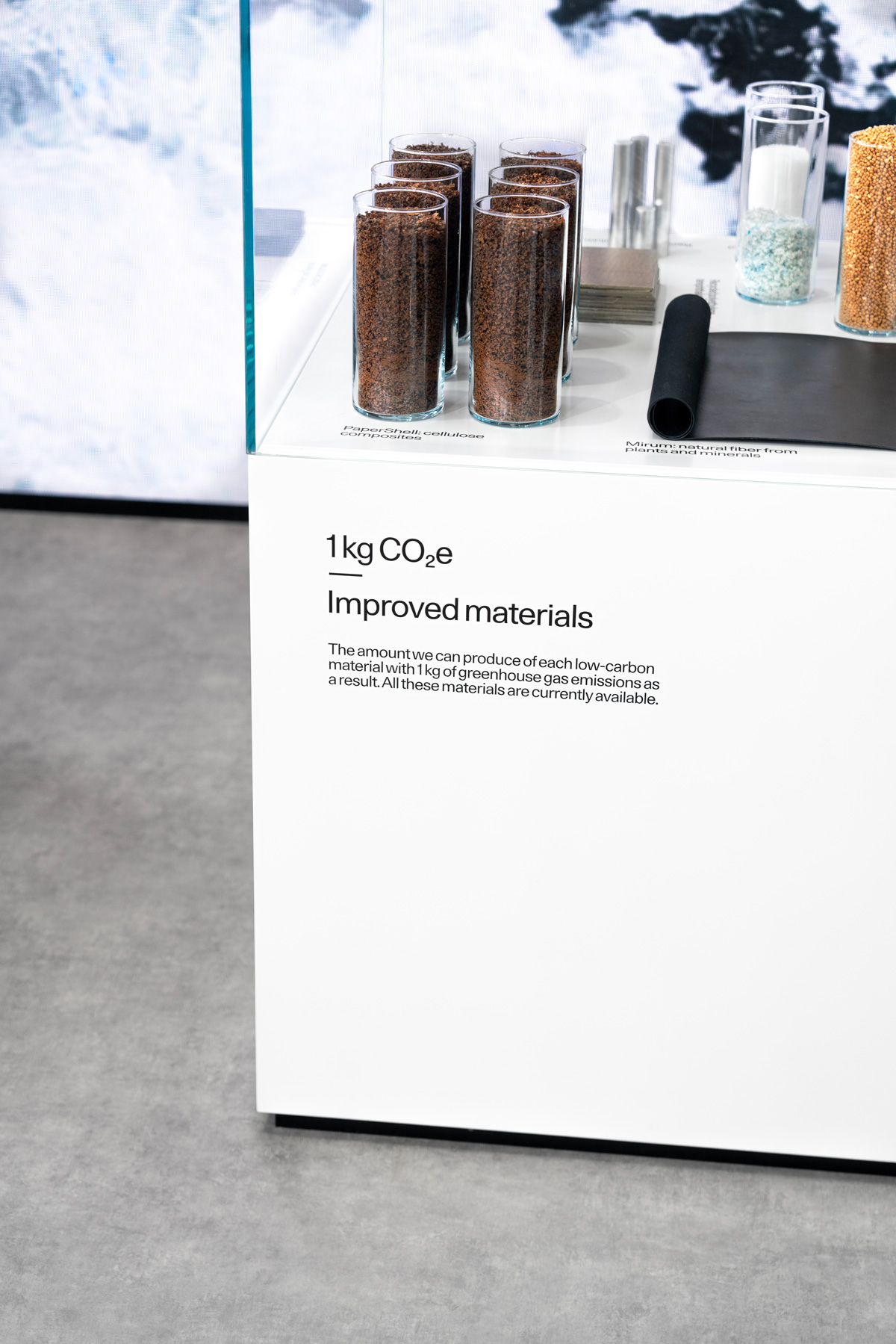

PaperShell at UN Climate Summit COP28 in Dubai 2023. Exhibited at Polestar’s material comparision clearly showing PaperShell’s potential.

PaperShell Information Package

How to reduce your emission (CO2e) with up to 98%: Key metrics when replace glass fibre, aluminum or plastic with PaperShell

Contact Us

For inquiries or booking appointments, please fill in the form below.

"*" indicates required fields